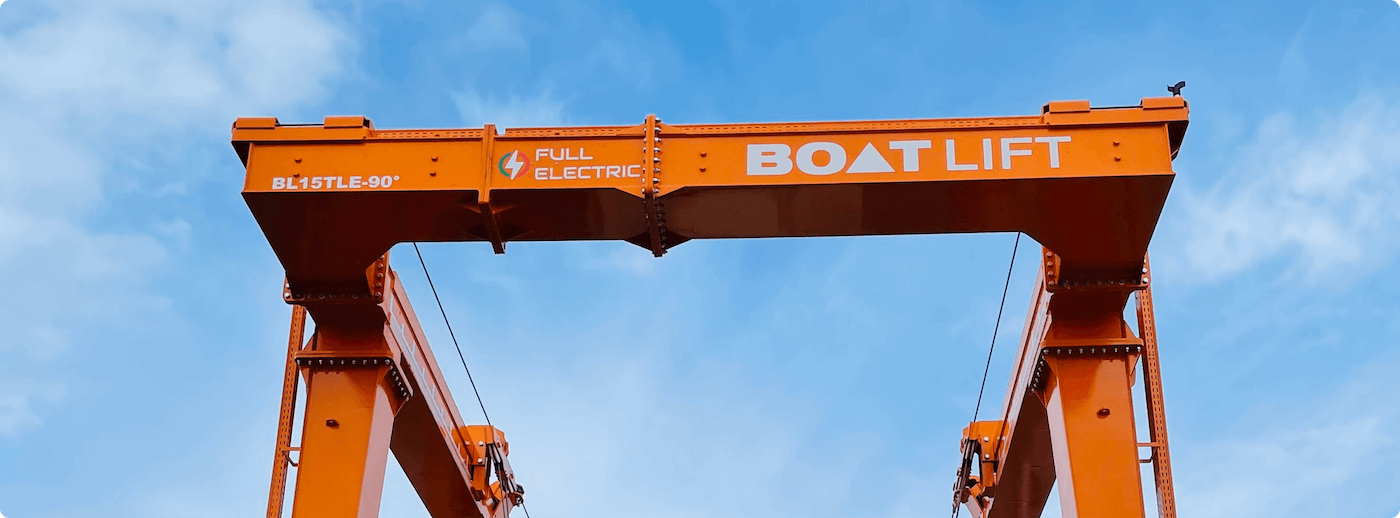

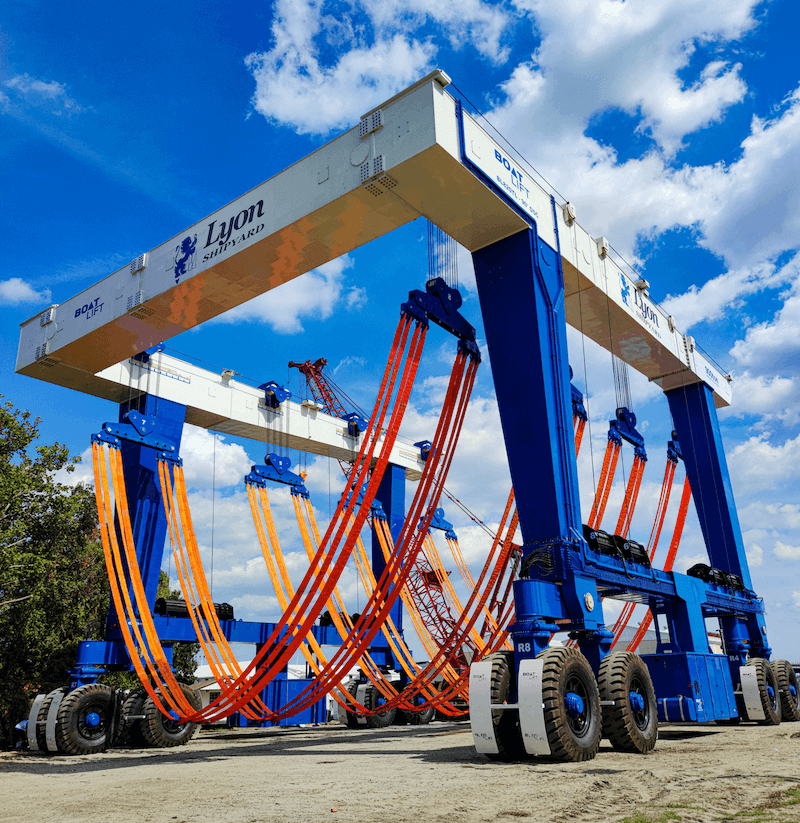

Travel lift

Discover our range of travel lifts, from 25 to 1500 ton. Tailor-made solutions, conceived to ensure the best functionality and ease of use.

MAIN FEATURES

Engineering and manufacturing process completely internalized

Machinery compliant to 2006/42/CE guidelines and to FEM / UNI EN standards

Customized dimensions according to customer’s needs

Soundproofed diesel engine compliant to current regulations

Anti-corrosion painting compliant to C5m cycle

Independent and electronically synchronized winches

Double proportional lifting speed unloaded / loaded

Lifting belts with safety factor 7:1

Double proportional motion speed unloaded / loaded

Industrial tyres, air-inflated or equipped with specific filling

Pipes and fittings in galvanized painted steel

Hydraulic oil filtering

Electrical supply by 12/24 VCC battery

Remote assistance in real time by M2M system

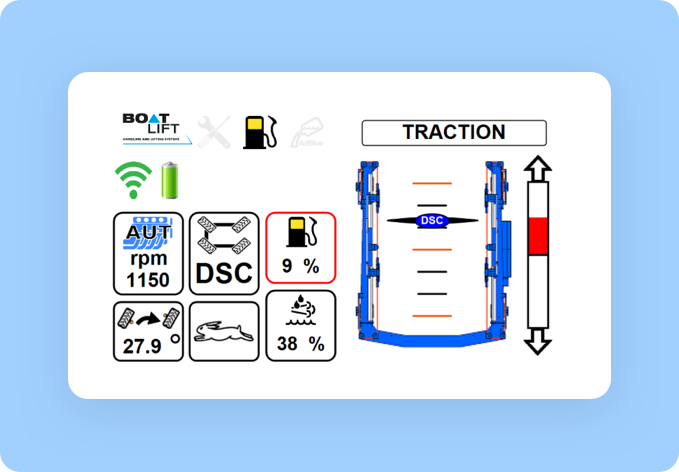

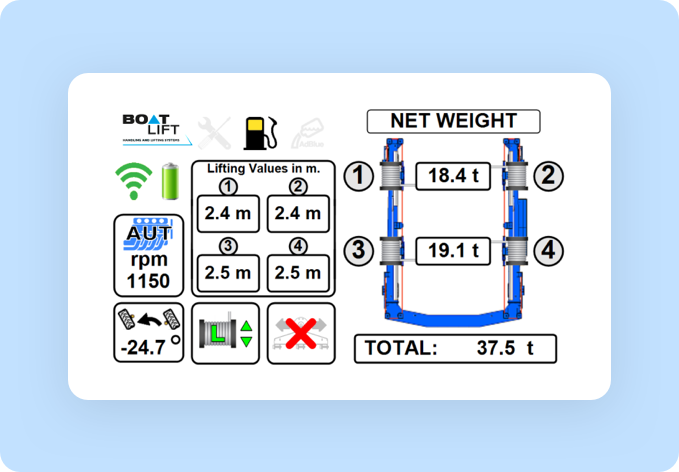

REMOTE CONTROL WITH LCD COLOR DISPLAY

The remote control guarantees ease of use and the highest lever of safety.

-

Partial/total weight reading system with warning threshold

-

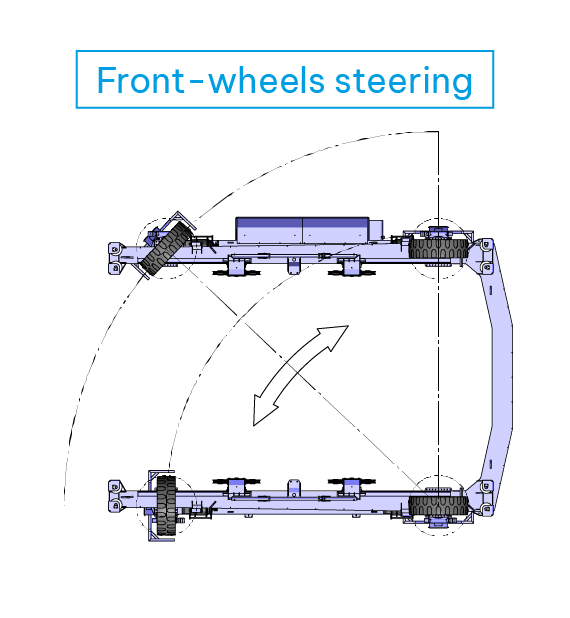

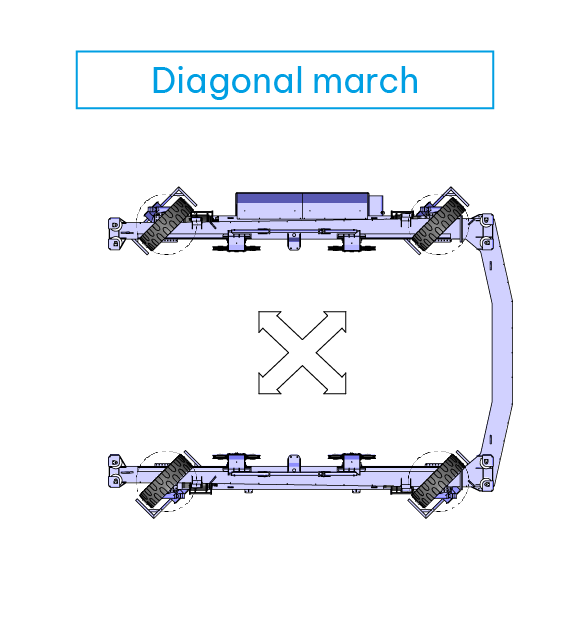

Monitoring of radius and of the selected steering mode

-

Lifting range of each pulley block

-

Engine operating status and residual range

-

Alarm light and scheduled maintenance

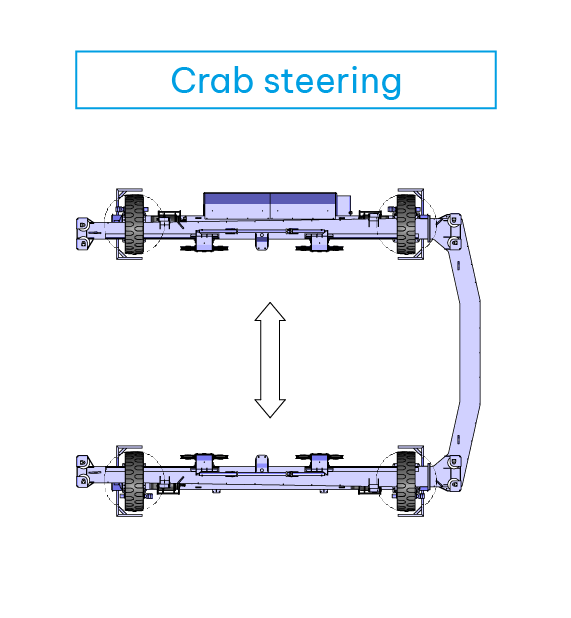

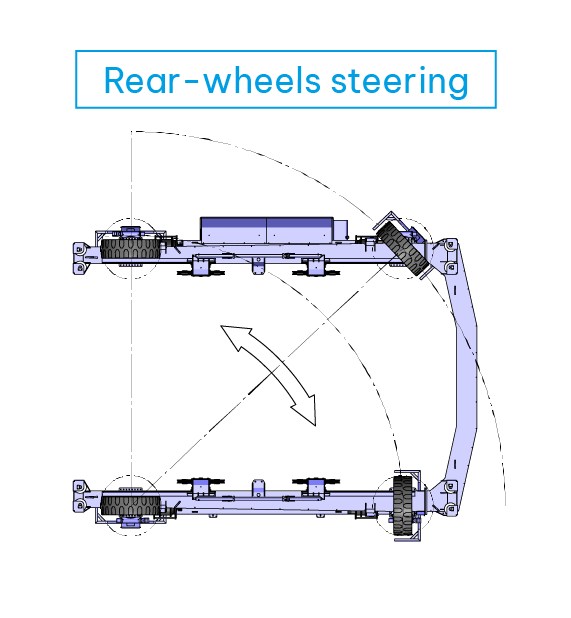

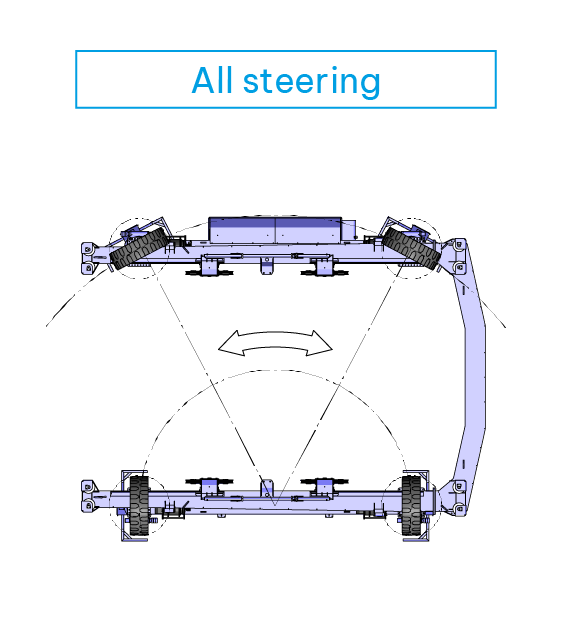

OPTIMAL MANEUVERABILITY PROVIDED BY THE STEERING MODES

MAXIMIZE THE USE OF SPACE WITH THE VARIABLE WIDTH TRAVEL LIFT

Thanks to the hydraulic telescopic expansion system, travel lifts may be supplied with adjustable track, allowing to optimize spaces in the work area and to meet different hull requirements.

MAIN FEATURES OF THE VARIABLE WIDTH TRAVEL LIFT

MANEUVERABILITY

The variable width TRAVEL LIFT allows to make the most of boat storage area, reaching spaces inaccessible with a standard TRAVEL LIFT and reducing the unused room among boats.

VERSATILITY

The hydraulic expansion system enables hauling and launching operations on piers with different widths. Besides, the possibility of reducing the overall dimensions allows easy access to sheds or enclosed spaces.

EFFICIENCY

It is possible to reduce or increase the track of the structure with loaded machine, ensuring operations at every stage of the expansion stroke.

SAFETY

All travel lift controls are remotely managed through radio control, in order to guarantee maximum safety during handling, hauling and launching operations.

FULL-ELECTRIC

PERSONALIZE YOUR MACHINE

Discover all available optionals to personalize your machine

-

Forward-placed crossbeam

-

Driver seat

-

Structure articulated through the “Trunnion Pin” system, in order to absorb any ground unevenness

-

Work area lighting with LED headlights

-

Auxiliary crane

-

Stainless steel pipes and fittings

-

Electronic “Dynamic Steering Control” with motorized slew drives for the best maneuverability

-

Anemometer

SELECT THE SIZE

Choose the size and download the technical sheet PDF.

Request information on this product

Please fill in the form below. We will reply within 1-2 working days

.png)

.png)